- Login

- Home

- MABA

- MABF

- What's New

- Events

- Resources

- Biosolids Advocacy Fund

- Contact Us

|

March 2024 - MABA Biosolids Spotlight Provided to MABA members by Bill Toffey, Effluential Synergies, LLC Sailing the Sludge Boat to Newark The job opening was posted recently for this job with New York City Department of Environmental Protection (NYC DEP) : Sludge Boat Captain. The minimum requirements for this public sector biosolids job are unusual in the biosolids business – the requirements include a “valid U.S. Coast License as Master of Coastwise steam or motor vessels.” Sludge boats? “Sludge boats” for which NYC is seeking a captain serve as the equivalent of pipelines for moving liquid digested sludge between New York’s Water Recovery REcovery Facilities (WRRFs) and its non-dewatering WRRFs and the WRRF facility in Newark operated by the Passaic Valley Sewerage Commission (PVSC). The “boats,” as they have been known for many decades, are not barges, but self-powered marine vessels. The era of ocean dispersal of sludges began in 1938 and ended in 1992 when this method of sludge management was banned. “Boats” were deployed to collect liquid sludge from each plant and discharge just 12 miles from the coast, followed by a period of discharge at mile 104, at the edge of the continental shelf. Then entered the period of dewatering and land based biosolids recycling, when the sludge boats became the “pipeline” for liquid digested sludge movement between WRRFs, to make optimal use of dewatering equipment and cake hauling. Thus, sludge boats have been a consistent part of the NYC marine and “sludge” experience.

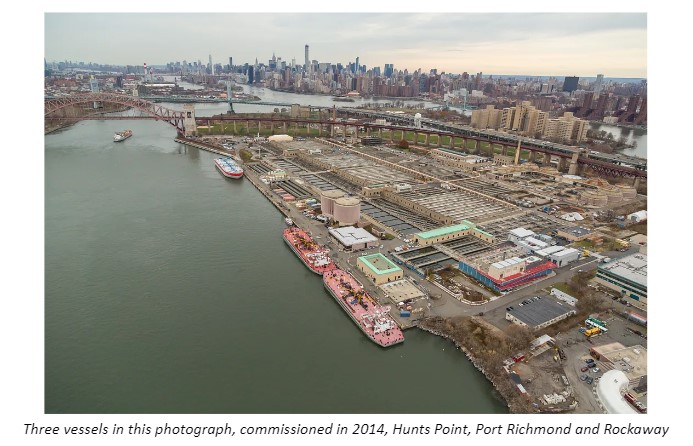

NYC DEP’s five marine vessels are staffed by 5 operators and one sludge boat captain. Each vessel is named after one of the agency’s WRRFs, which is appropriate for their role in transporting liquid digested sludge from eight WRRFs not served by onsite dewatering facilities to those six that are equipped with dewatering centrifuges. The North River (commissioned in 1974) is the last remaining vessel originally built for ocean disposal of liquid sludges. The Red Hook (2008) can transport over one million gallons of sludge and is the largest boat in the fleet at 352 feet. The three newer vessels, each with the capacity to carry 1 million gallons of liquid sludge, were commissioned in 2014 and are named the Hunts Point, the Port Richmond and the Rockaway. At a total construction cost of $106 million, these three are equipped with the latest marine technology, have a greater cargo capacity and more versatility than the older models, including a shallower draft, which allows them to have no bridge height restrictions in serving the treatment plants. Operations of the vessels are 24/7, 365 days a year, and their movements stretch out to all five boroughs, including the bays, rivers and creeks that make up greater New York Harbor. All told, the “boats” move about 75 million gallons monthly, or 900 million gallons of liquid digested sludge annually.

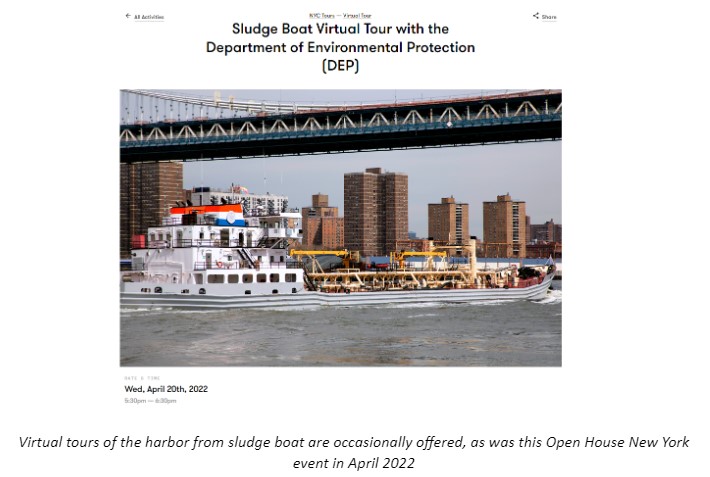

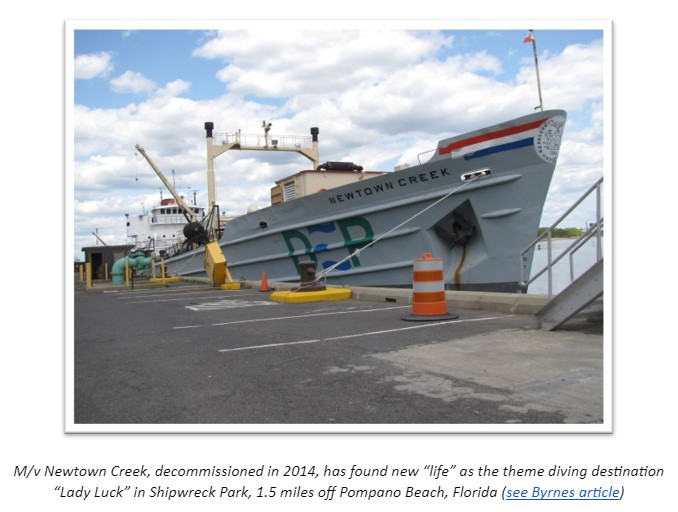

Arguably, no job in the entire Mid-Atlantic region is more critical to the environmentally sound management of biosolids than that of the sludge boat captain. The sludge boat captain has an intriguing set of job requirements. The captain acts as the pilot navigating the vessel throughout the NY Harbor and duties include “responsibility for the safe operation of the vessel at all times,” “inspect the ship at frequent intervals; and maintain proper upkeep of the vessel.”. The draw of being a sludge boat captain may be in the local fandom of sludge boat operations. NYC DEP’s chief of Residuals Operations Kevin Byrnes, a 40-year employee of NYC DEP, has the Marine Section under his command. The story of the Maritime Division operations and its history is told in 80 Years of Maritime Excellence, and mirrors the evolution of biosolids management in the United States. The sludge boats have been a consistent part of the maritime scene around NYC. On the occasion of its “retirement” after 47 years of service, the M/v Newtown Creek was recognized by Byrnes in an article he wrote: From the First Splash to the Last: a Ship that Keeps on Giving. The fascinating program, Open House New York (OHNY), has offered a virtual sludge boat tour (April 2022) on Zoom, DEP Sludge Boat Tour. Only a few select ticket holders could enjoy the nine-hour tour on 16 August 2023, DEP Experience Tour: Sludge Boat, but all folks can sign up with OHNY for the next marine tour, even if it is only a virtual tour. The news media is also a fan of the sludge boats (Sailing Round Manhattan on the Sludge Boat and Sludge Boats: Out of Sight, but Never Out of Mind).

One of the unique ports of call for the NYC DEP marine vessels is Newark, New Jersey. For two decades, the PVSC in Newark has been receiving deliveries of liquid digested sludge from various WRRFs. PVSC is one of the largest WRRFs on the East Coast US, with a designed capacity of 330 million gallons per day (MGD), and it is the nation’s largest facility for regional acceptance of trucked in liquid wastes. Its Liquid Waste Acceptance Program (LWAP) was initiated in 1996, after PVSC had lost the influent of several major industrial customers within its waste watershed. NYC joined PVSC LWAP program in 2004, with just a few barge loads monthly.

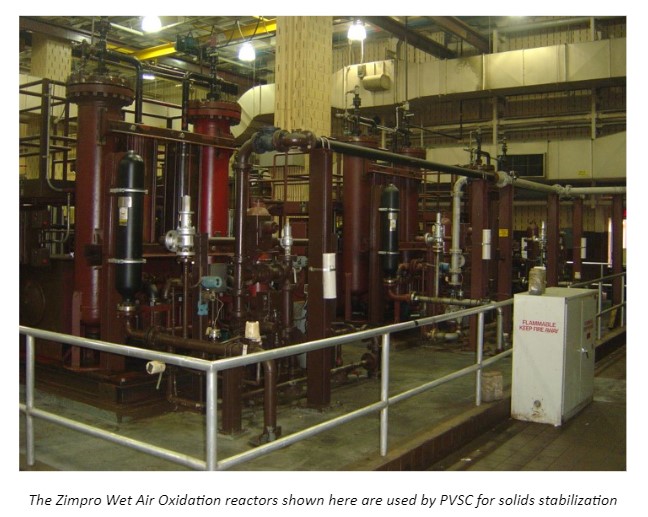

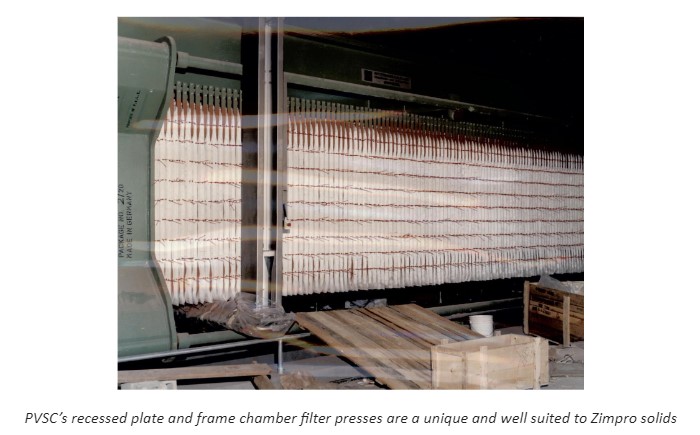

By the time the most recent 5-year intergovernmental agreement had been signed between NYC and PVSC in 2023, NYC was delivering about 200 million gallons yearly, ensuring NY’s outlet in Newark will remain a component of New York’s evolving biosolids program for the foreseeable future.  The PVSC biosolids treatment system is itself unique in the nation. First, it has the nation’s only Zimpro Wet Air Oxidation (WAO) system which accomplishes extraordinary volatile solids destruction and pathogen reduction under high temperature and pressure. The injection of oxygen into the Zimpro reactors distinguishes this thermal process from the array of other related processes, such as hydrothermal liquefaction, gasification, pyrolysis and supercritical water oxidation, which have attracted renewed interest in the field of wastewater engineering. Unlike these newcomers, PVSC’s Zimpro equipment has been in operation for over 40 years and its operational, maintenance and in-house fabrication capabilities have played a large part in the longevity of the Wet-Air Oxidation process equipment. Post WAO stabilization, solids are dewatered by a set of recessed plate and frame chamber filter presses, also one of two installations of this class of dewatering presses remaining in the United States, but one well suited to the unique qualities of WAO residuals. PVSC’s robust preventive and maintenance program on its Zimpro equipment and the on-going rehabilitation of the Decant and Filter Press Facility will continue to give PVSC the ability to accept and process NYC DEP liquid digested sludge.

Sludge “boats” arrive at PVSC 5 to 7 times a week. This comes to about 200 million gallons of liquid sludge annually. PVSC’s sludge thickening, thermal sludge conditioning (Zimpro) and dewatering sludge process greatly reduces NYC DEP’s liquid digested sludge, in effect reducing by 70% the mass of residuals attributable to NYC. The PVSC process results in a residual that is qualified by New Jersey Department of Environmental Protection (NJDEP) for use as alternative daily cover at municipal solid waste landfills, which New Jersey credits to in-state beneficial use.

NYC DEP is only one of PVSC’s customers for liquid digested sludge deliveries, and it is also not the only customer that delivers by the water route. Bergen County Utilities Authority is the second largest source of imported solids to PVSC via barge. Just over 100 other customers from industrial and municipal wastewater sources in New Jersey deliver upwards of 200 truckloads daily under PVSC’s LWAP. For more information, contact Mary Firestone at [email protected] or 845-901-7905.

|